In the realm of construction, small-scale projects often present unique challenges. Balancing quality, efficiency, and cost-effectiveness may be a delicate balance, especially regarding precast panel details. This post will look at cost-effective solutions for precast panel detailing that can assist small-scale projects. From leveraging technology to maximizing expertise, we’ll uncover the key strategies to ensure the success of your next project.

Understanding the significance of Precast Panel Detailing

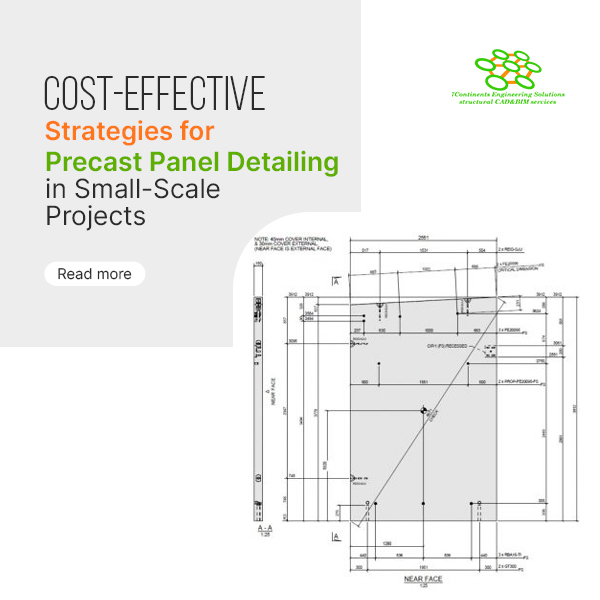

Before we get into the techniques, it’s essential to grasp the significance of precast panel detailing. Precast panels are an essential component of many construction projects, offering advantages such as shorter construction time and enhanced control of quality. Precise detailing ensures that these panels are correctly manufactured and installed, making it a critical aspect of construction.

1. Leveraging Advanced Technology

In today’s digital age, utilizing new technologies can significantly improve the efficiency of precast panel detailing. This includes using Computer-Aided Design (CAD) software to create precise and error-free panel shop drawings.

2. Experts Detailing Services

Small-scale initiatives necessitate close attention to detail. Working with professionals in precast panel details, such as 7Continents Engineering Solutions (7CES), guarantees that you have access to the highest degree of experience. Their expert detailers can generate error-free shop drawings, ensuring that your project stays on track.

3. Modular Design

In small-scale projects, optimizing resources is crucial. Modular design ideas might assist you in reducing waste and increasing efficiency. Precast panels can be engineered to smoothly fit together, minimizing the requirement for specialized components and reducing expenses.

4. Material Selection

Picking the right materials may lead to significant cost savings. Opt for materials that are easily available and reasonably priced without compromising quality. Consult your detailing professionals to determine the finest solutions for your specific project.

5. Streamlined Manufacturing

Manufacturing efficiency is essential. Collaborate with precast manufacturers who have experience with small-scale projects. Their experience with the complexities of smaller works can lead to faster turnaround times and cost savings.

6. Quality Assurance

While cost-effectiveness is essential it should not come at the expense of quality. Implement strong quality control procedures throughout the detailing and manufacturing phases to ensure that your precast panels satisfy the highest requirements.

7. Project Management

Effective project management is key to keeping costs in check. Utilize project management tools and procedures to track progress, properly allocate resources, and identify potential cost-saving opportunities.

Conclusion

In the world of small-scale construction projects, cost-effective precast panel detailing solutions are crucial. Leveraging technology, collaborating with experts, and implementing innovative ideas can make all the difference. By implementing these tactics, you can ensure that your next small-scale project is not only cost-effective but also precise and high-quality.

Trust 7CES (7Continents Engineering Solutions) for the best-precast panel detailing services. Their skilled team is dedicated to delivering error-free precast panel shop drawings, assuring the success of your small-scale project.